WhatsApp: 683 44 26 08

E-mail: info@panelsandwich.org

The use of profiled sheet for roof and facade cladding is a technically and economically competitive solution.

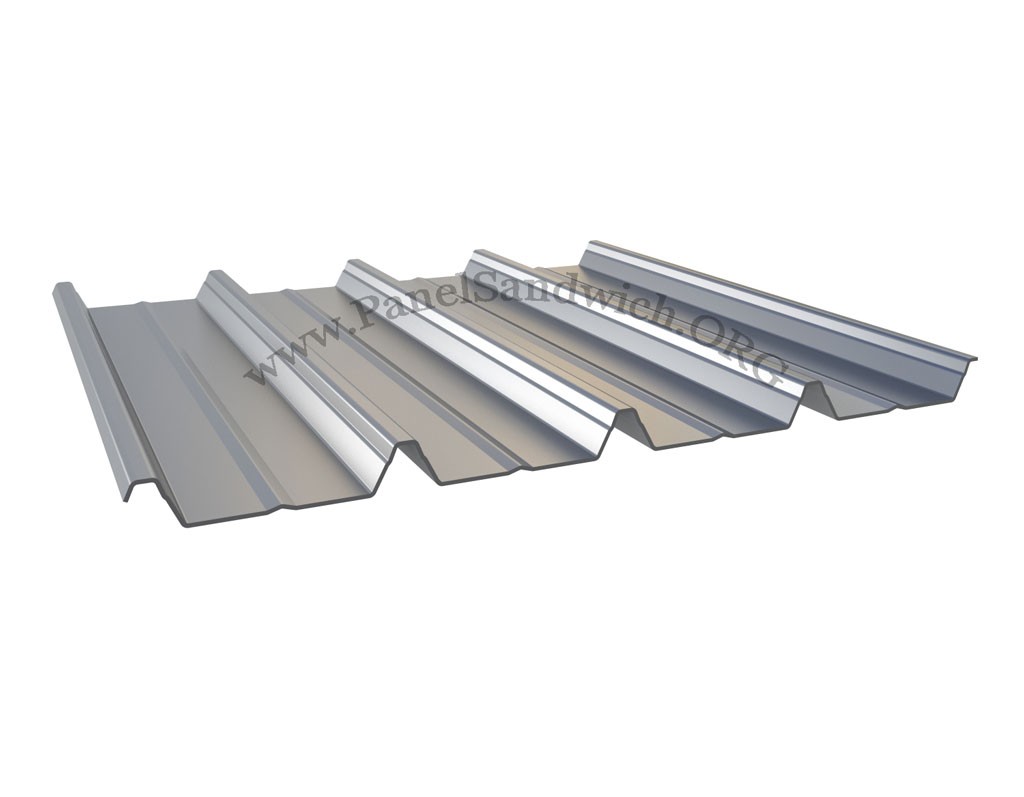

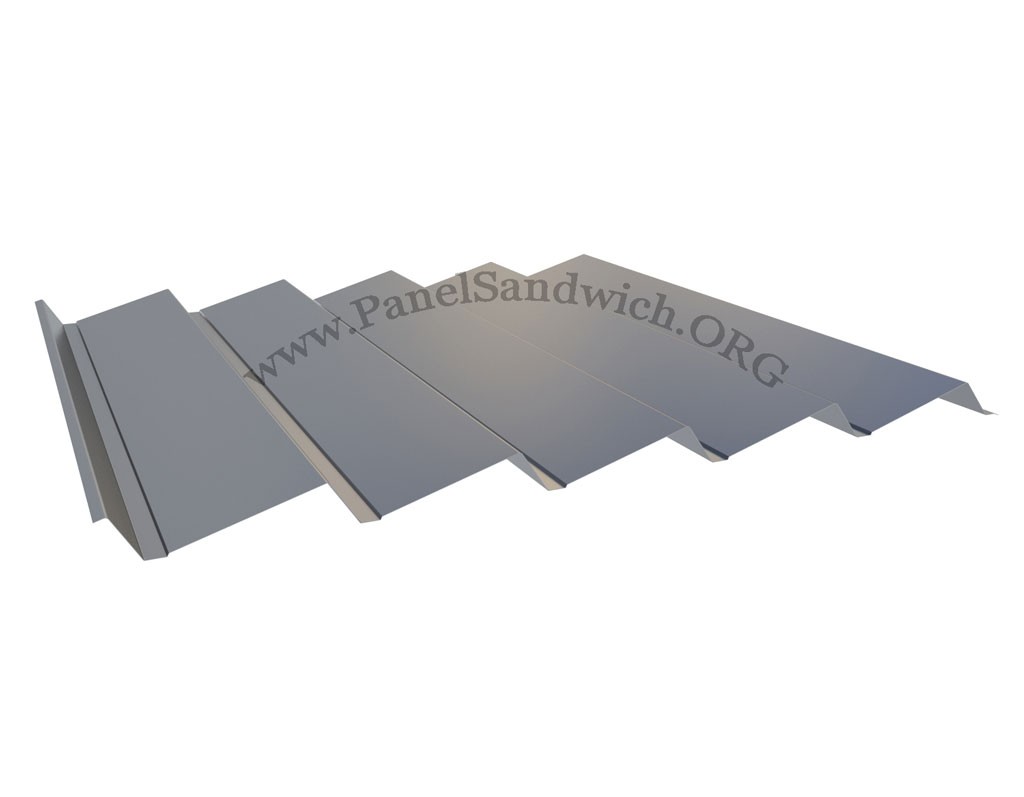

By varying the thickness of the plate and the geometrical characteristics of the section, we can obtain lightweight components capable of overcoming different spans.

The different profiles are obtained by roll-forming coils of pre-painted or galvanized cold-rolled sheet metal.

The profiled sheet can be corrugated or trapezoidal, with variable profile heights, spacing, dimensions and may or may not have rigid ribs.

In order to provide better thermal and acoustic insulation, a layer of insulation is used between the two cladding sheets.

The secondary structure is fastened with galvanized screws, stainless steel self-tapping screws or self-drilling screws.

In the same type of sheet metal, we also manufacture all the necessary accessories for a correct waterproofing, in particular: ruffles, ends, ridges, drips, etc.

We assemble sandwich panels thanks to our own team specialized in roof assembly. We take care of the necessary measurements, material supply, transport and lifting methods. Leave everything in our hands for the renovation or new construction of our sandwich panels. If you need asbestos removal, we have equipment, EPIS and personnel prepared to perform it, all in compliance with current regulations.

Our technical office reviews all the products and materials necessary for the installation of panels, trims and fasteners. We offer our customers new and second-hand panels as well as second-hand panels at the best prices on the market. The advantages of the polyurethane sandwich panel are that it is lightweight, ideal for enclosing roofs or facades and is highly insulating.

Do you need personalized advice?

Contact us and we will answer any questions you may have about our sandwich panels, their installation and applications.

131 Palauet Street

Catalunya – Lleida – 25001

info@panelsandwich.org

Tel: +34 973 22 81 64

Mobile: +34 683 44 26 08