WhatsApp: 683 44 26 08

E-mail: info@panelsandwich.org

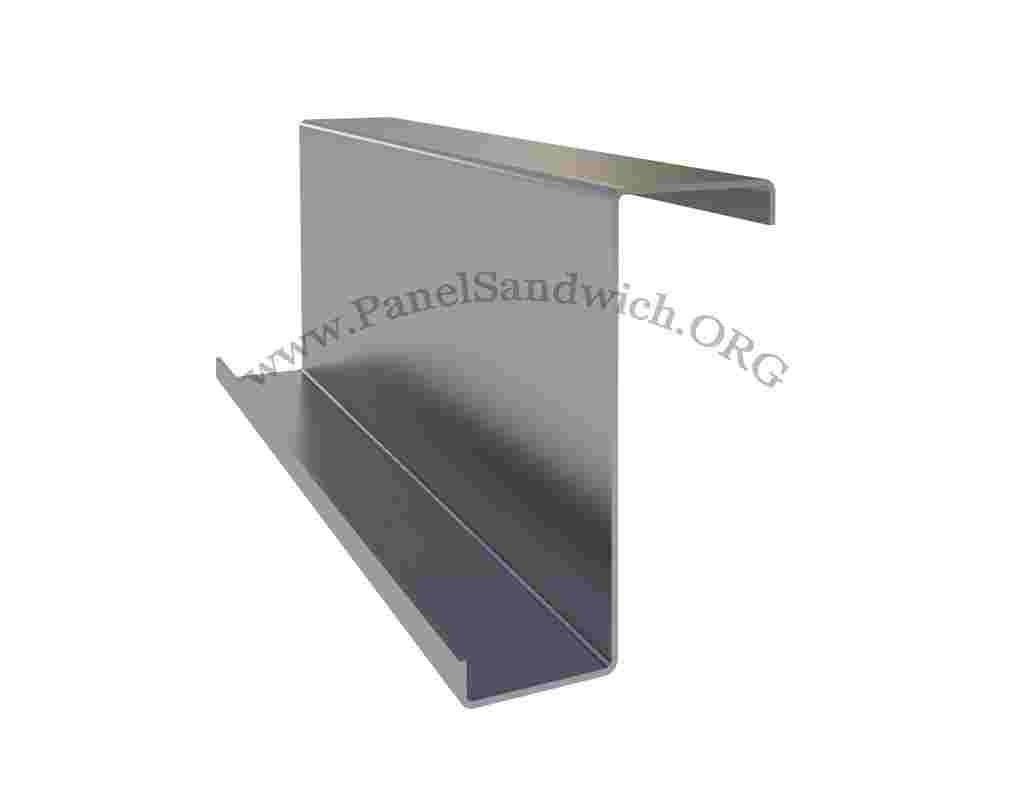

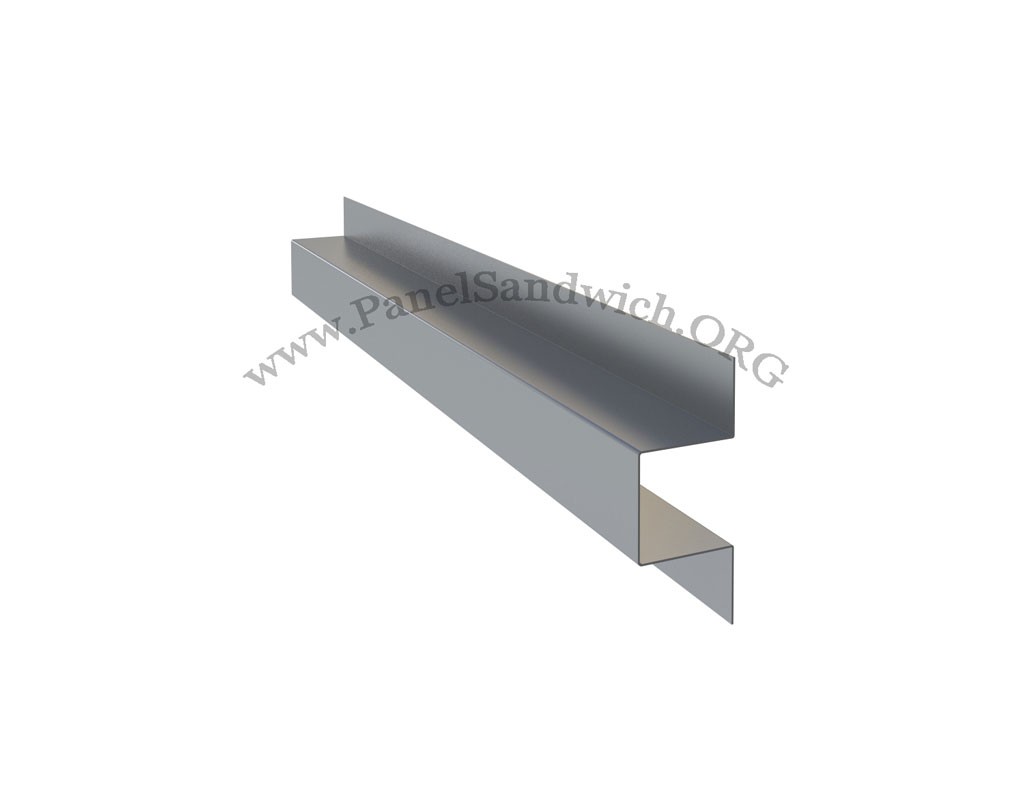

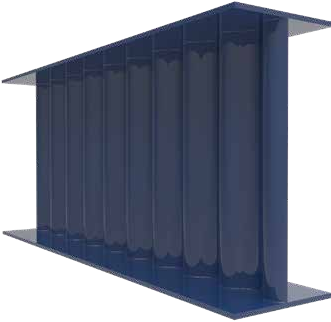

Cold-formed mild steel C and Z sections have many advantages compared to hot-rolled steel sections. Weight versus strength is a characteristic that has led to the exponential growth of the use of these sections in the construction of buildings of the most varied typologies. Therefore, this document contains the properties of the gross section and the effective section of the C and Z section profiles currently produced by Panel Sandwich .ORG.

REQUEST PRICE AND TECHNICAL INFORMATION

The application of cold-formed steel profiles has shown exponential growth as a result of the enormous advantages of the application over other competing solutions.

The C and Z profiles mentioned in the catalog are manufactured in pre-galvanized steel according to EN 10346 with a zinc grade varying between Z10 and Z275, depending on the project requirements. Optionally, this product can be supplied with another type of surface finish, specifically with RAL lacquer to be defined.

Within the scope of current European standards, the dimensioning of cold-formed mild steel sections (class 3 and 4) is carried out using Eurocode 3 Design of steel structures, parts 1.1, 1.3 and 1.5. These standards present models for the design of elements subjected to different types of stresses acting alone or in combination, based on effective properties. The sections treated here comply with the restrictions set forth in the EN 1993-1-3 standard regarding maximum limits between the ratio of the different widths.

The cross-sections and the corresponding geometrical properties were obtained separately for pure compression, bending in accordance with and bending in accordance with z. However, these properties may be used in the verification of sections subjected to combined stresses, as provided for in clauses 4.3(3) and 4.3(4) of the standard. EN 1993-1-3.

The tables presented in this catalog contain the properties of the gross section and the effective sections (in compression and bending) of the C and Z section profiles that make up our range. As for the effective cross-section, the moments of inertia and the elastic bending modulus in the y and z directions are presented, considering positive and negative bending moments, as well as the effective area and the position of the center of gravity in relation to the initial position. (gross section) for pure compressive stresses.

To determine the effective properties of the Z sections, a simplification was considered, which consists of calculating the properties for the same system of axes of the C section, i.e., according to the horizontal and vertical axes, although they are not the main axes of inertia of the C section. section.

In order to allow the transmission of continuity stresses in splicing situations, standardized connections were defined for each of the situations depending on the type of profile. Polyurethane (PUR) : Polyisocyanurate (PIR)

C metal straps C profiles are supplied with holes for bolting to the main structure by means of accessories.

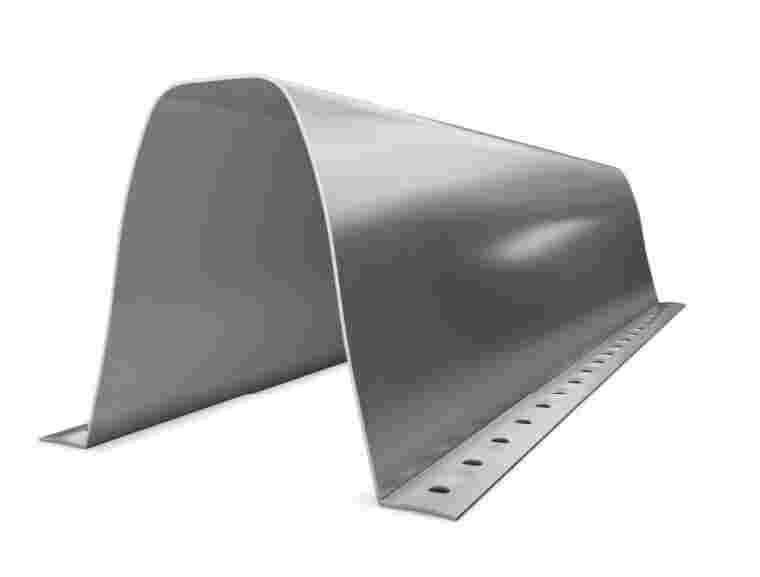

We assemble sandwich panels thanks to our own team specialized in roof assembly. We take care of the necessary measurements, material supply, transport and lifting methods. Leave everything in our hands for the renovation or new construction of our sandwich panels. If you need asbestos removal, we have equipment, EPIS and personnel prepared to perform it, all in compliance with current regulations.

Our technical office reviews all the products and materials necessary for the installation of panels, trims and fasteners. We offer our customers new and second-hand panels as well as second-hand panels at the best prices on the market. The advantages of the polyurethane sandwich panel are that it is lightweight, ideal for enclosing roofs or facades and is highly insulating.

Do you need personalized advice?

Contact us and we will answer any questions you may have about our sandwich panels, their installation and applications.

131 Palauet Street

Catalunya – Lleida – 25001

info@panelsandwich.org

Tel: +34 973 22 81 64

Mobile: +34 683 44 26 08