WhatsApp: 683 44 26 08

E-mail: info@panelsandwich.org

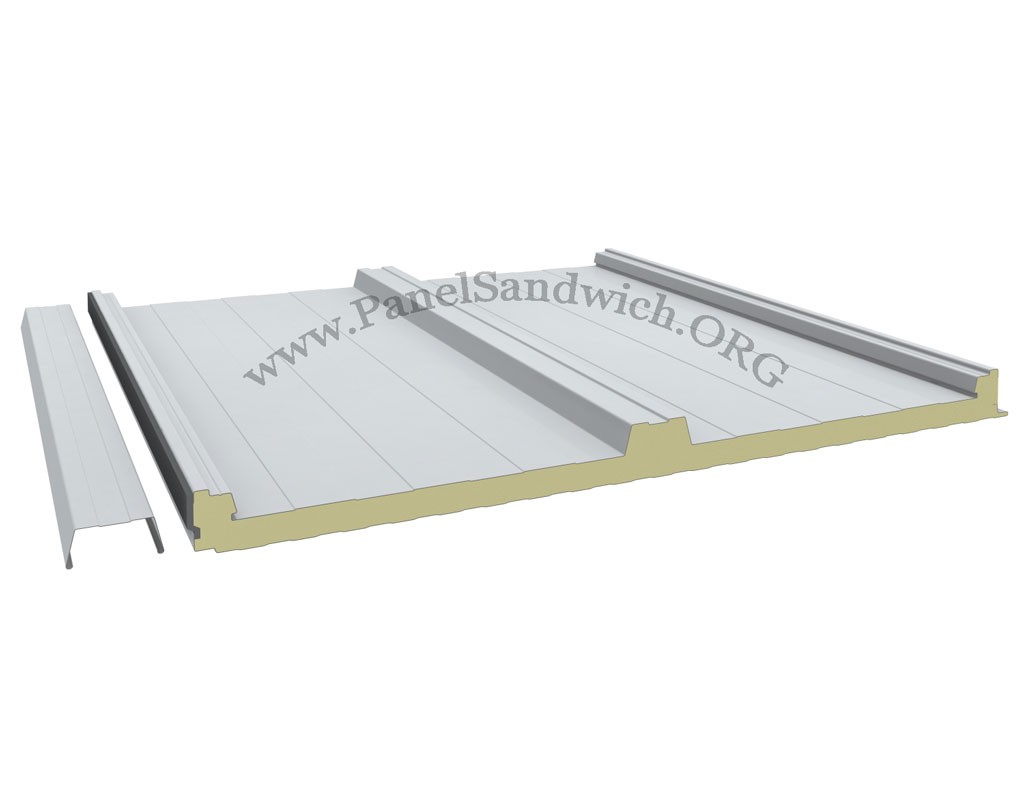

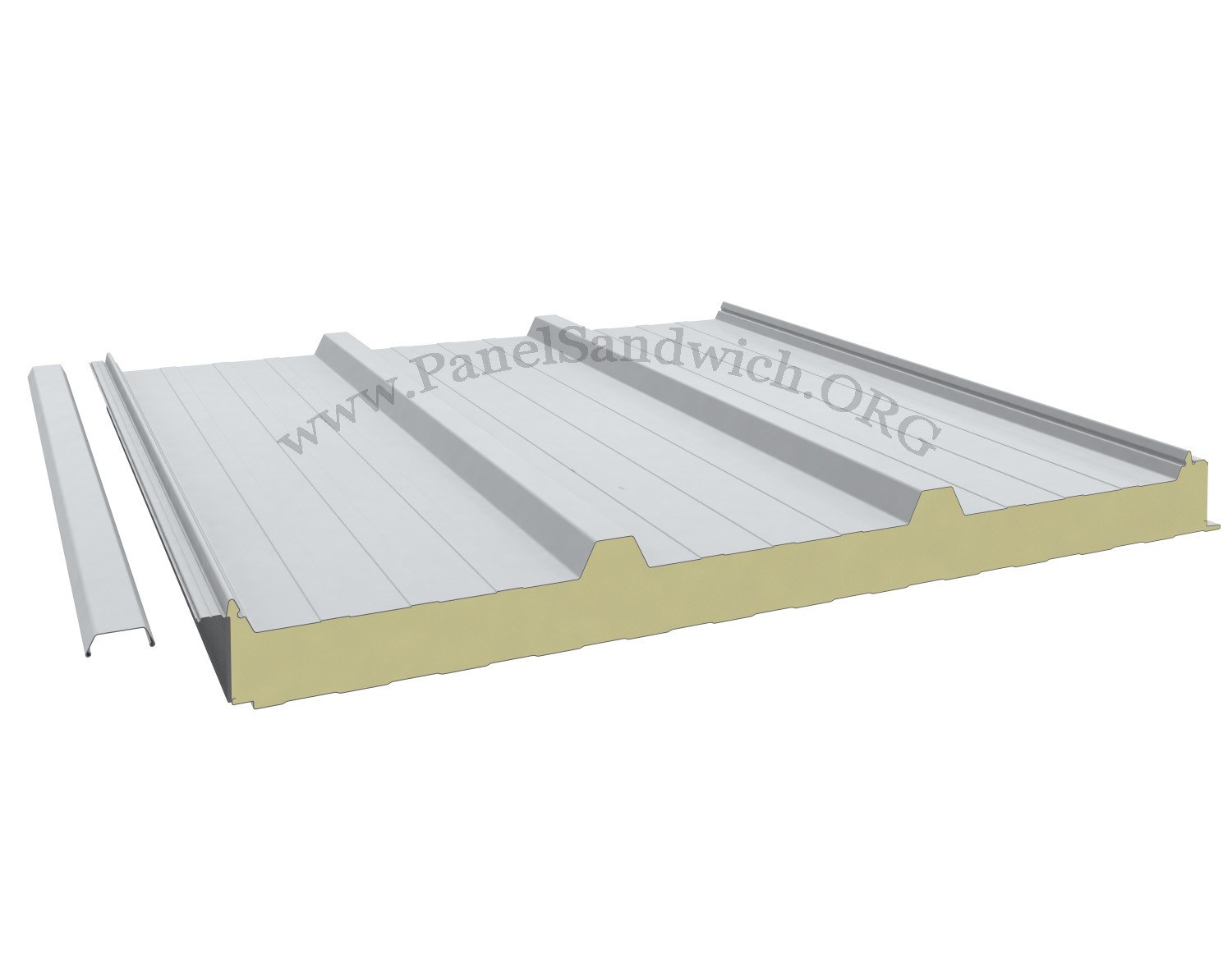

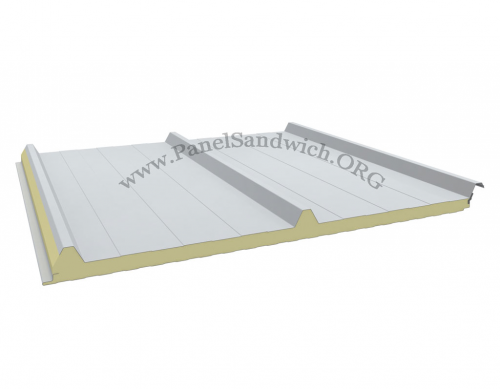

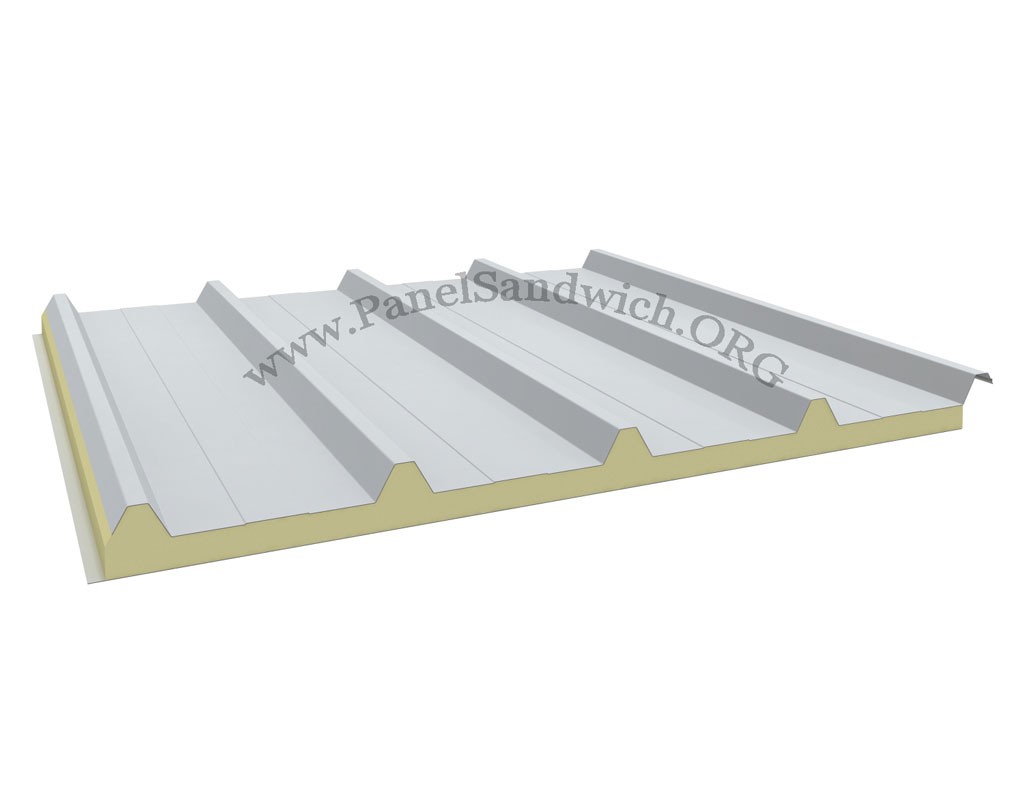

3-fluted roof panel applicable on one-piece roofs with a minimum slope of 7%. The panel has a high mechanical resistance and full guarantee of watertightness on any supporting structure, be it wood, steel or concrete.

The panel is the most economical in its range, but without sacrificing performance or quality. The panel has a central rib, an outer and an inner sheet with a core of polyurethane 40 kg/m3 which makes it self-supporting and therefore very resistant.

The panel can be manufactured in different veneer finishes according to the customer’s needs and with the color of the existing range, the most usual being white or red.

This panel is multi-purpose and is suitable for agricultural buildings, industrial buildings and roofs in general.

The panel is assembled very quickly thanks to its overlapping system that fits one on top of the other.

Panel characteristics:

|

Inner side |

0.4mm steel |

|

Inner side |

0.4mm steel plate |

|

Isolation |

40 kg/m3 polyurethane |

|

Type of plate |

Lacquered 5 microns |

|

Fire Resistance |

CS3D0 /BS2DO |

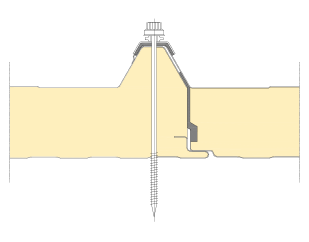

Type of joint and fasteners

Type of joint: Socket type. The screw is visible and is mounted with a washer to prevent water and wind entry.

Screws: Screw with rubber washer.

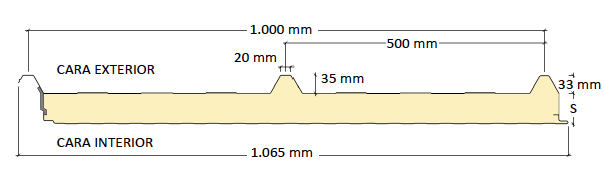

Panel size:

Panel Measurement: Useful width of 1.00 m. x Factory length as per customer’s request.

Available factory sizes: The length of the panel is made to the size of the cover with a limit of 13.50 meters for transport, being possible to manufacture a longer panel but taking into account that we need a special transport.

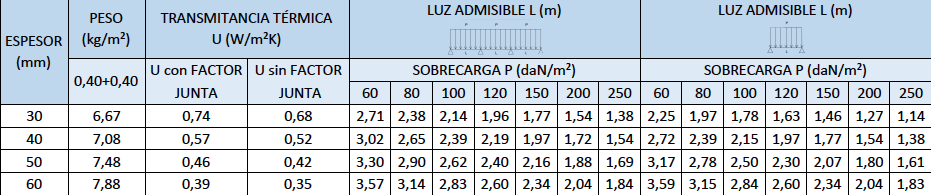

Load table:

Permissible values with steel thicknesses of 0.4 or 0.5 mm on the outer face and 0.4 mm on the inner face. The l spans in meters corresponding to the uniformly distributed overload (daN/m²) have been obtained in the load tests carried out in our laboratories and simultaneously guarantee a date f.l/ and u200 n safety coefficient in compliance with the UEAtc standards for sandwich panels, which have been drawn up and are applied by the main European certifying bodies.

We assemble sandwich panels thanks to our own team specialized in roof assembly. We take care of the necessary measurements, material supply, transport and lifting methods. Leave everything in our hands for the renovation or new construction of our sandwich panels. If you need asbestos removal, we have equipment, EPIS and personnel prepared to perform it, all in compliance with current regulations.

Our technical office reviews all the products and materials necessary for the installation of panels, trims and fasteners. We offer our customers new and second-hand panels as well as second-hand panels at the best prices on the market. The advantages of the polyurethane sandwich panel are that it is lightweight, ideal for enclosing roofs or facades and is highly insulating.

Do you need personalized advice?

Contact us and we will answer any questions you may have about our sandwich panels, their installation and applications.

131 Palauet Street

Catalunya – Lleida – 25001

info@panelsandwich.org

Tel: +34 973 22 81 64

Mobile: +34 683 44 26 08